If there’s one piece of equipment you’ll find in almost any modern manufacturing unit, it’s an industrial printer. These robust machines are the workhorses behind labeling, tracking, and even decorating products as they roll off the production line. But for all their utility, installing one can be a bit of a challenge. That’s why we’ve put together essential tips for a successful installation of your industrial printer.

Understanding Your Industrial Printer

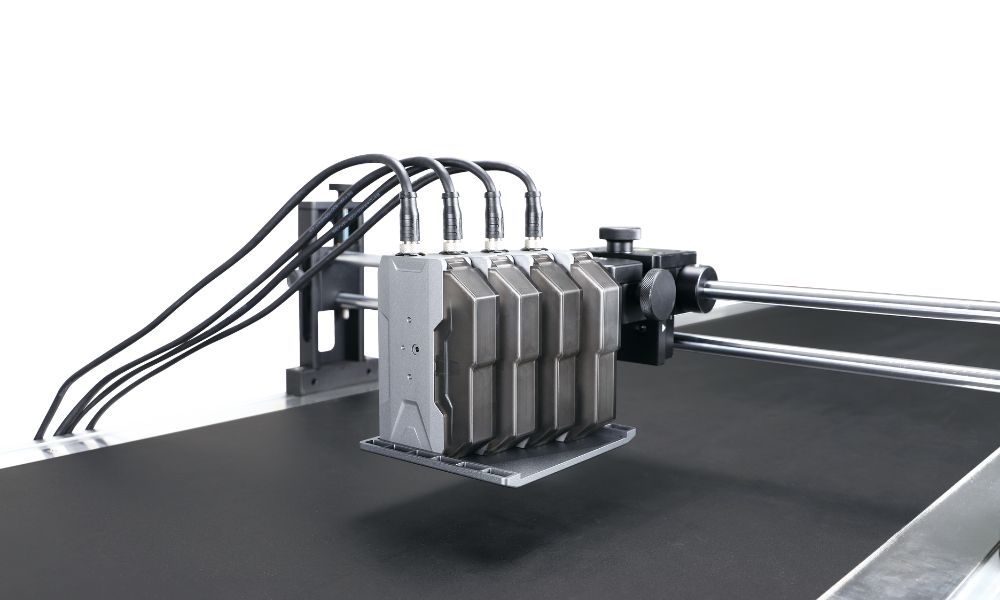

Before the installation process begins, it’s crucial to fully understand the type of industrial printer you’re dealing with. There are various versions specialized for different tasks, from basic black-and-white print on packaging to high-resolution color printing on metallic and labels.

The selection process is critical because using the wrong printer for your specific needs can lead to losses in production and quality. Make sure you select the right model before proceeding with installation.

If you’re looking for an inkjet coding and marking system, Tourmaline Enterprises offers a range of industrial printers designed to meet different industrial printing needs. Contact us for expert advice on the best printer for your business.

Preparing for Installation

Installation day shouldn’t be chaotic. Planning and preparation ensure a smooth process. Start with a comprehensive checklist of tools and parts you’ll need—everything from brackets and screws to voltage meters and wiring connectors. Don’t forget to adhere to safety protocols.

Checking the installation site for suitable conditions should also be part of your prep. The printer will need a stable, level surface and adequate space for both operation and maintenance. You should clean the site, remove any obstructions, and ensure proper ventilation for efficient operation.

Installing Your Printer

The actual installation can vary widely depending on the type and manufacturer of your industrial printer. However, there are some general steps you can anticipate. Carefully unpack your printer following the instructions provided. Assemble any necessary components, being sure to tighten all bolts and screws to prevent vibrations from disrupting printing.

If there are any electrical or network hookups that require expert knowledge, it’s always best to involve a certified technician. After all, incorrect connections can lead to malfunctions and potential safety hazards.

Testing and Maintenance Tips

Once your industrial printer is installed, the work isn’t over. First, conduct thorough tests to ensure the printer is functioning correctly. Test printing on various materials and at different speeds to mimic real-world conditions. This step allows you to tweak settings for the clearest and most accurate print possible.

Regular maintenance checks are essential to lengthen the printer’s life and keep it in peak condition. Dust and debris can quickly accumulate, affecting print quality and potentially causing damage to sensitive parts. Develop a routine maintenance checklist for daily, weekly, and monthly tasks.

The installation of an industrial printer is as important as the machine itself. Following these tips on properly installing an industrial printer will ensure a smooth, successful installation and maximize the productivity of your manufacturing unit. Remember to always consult the manufacturer’s guidelines for specific instructions and troubleshooting tips. With proper understanding, planning, and maintenance, your industrial printer will be a valuable asset for years to come.